Introduction:

The weave will not run parallel to the cut edge, therefore any wave, bow or skew in the products is normal due to the way of woven. The tolerance for bow and skew is max 3,8cm (1,5 width) or 5cm (2m width) in either direction. Some patterns will also exhibit a light and dark shading in the material, that is also normal. This shading is also evident at the seams where two pieces of the same style may have a different shade.

You may find some white threads going out of border, this normal occurrence, simply cut them with a scissor, it will not affect product quality and total appearance.

Installation:

Sub floor preparation:

The floor need to be clean, flat, no crack and oil stain free, pressure resistant and durable dry. Appropriate preparation is essential for a good result. The surface is treated with a primer, followed by the application of a leveling compound. This compound is grinded and vacuum cleaned. Take heed, depending on the construction of the floor, of the allowed residual humidity and possible rising moisture. If necessary, apply a damp screen.

Floor preparation:

Roll the floor covering out, overlapping for about 5 cm and leave 24 to acclimatize.

Always lay all the rolls in the same direction. Avoid crosscut seams and use transition profiles if this can not be prevented.

When laying several rolls in the same room, the rolls must be the same batch.

To obtain the best results, 48 acclimatization is advised and during installation the temperature should not be lower than 15 degrees Celsius and relative humidity not higher than 80%.

Seams: To cut the seams, trim the first carpet lane 2mm from a line or the trip of the design with a straightedge. The first lane is laid over the second lane and serves, as after matching the design, as a guide to cut the second lane and serves, after matching the design, as a guide to cut the second strip. Seams in references with an all-over design can be double cut.

Adhesive application: The carpet is to be bonded to the entire surface using suggested glue. Certain glues cause plasticizer migration often resulting in claims; these are nit covered by our warranty. (We suggest Mapei glue for installation). Respect the processing instructions of the manufacturer or contact your supplier.

Fold the lanes back over half of their length or (width) draw a line as start for the glue application. Lay the floor in the wet glue and rub with a cork beam from the center to the edges to remove all air bubbles. It is important to close the seams very well. During the drying time of the glue indoor conditions have to remain constant.

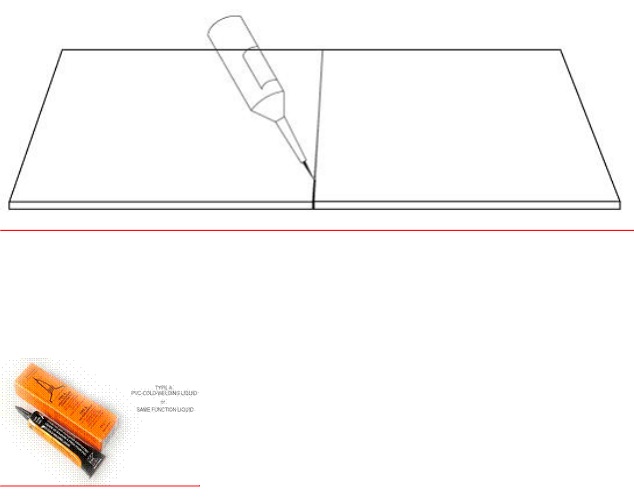

Welding of the seams (joints) :

It is necessary to weld the seams, we suggest to use a cold welding system of the Werner Mueller brand, type A.

Installation glue proposal:

Permanent – F. Ball & Co F44, F46, F48 Plus, F49.

Vertical – F. Ball & Co F49, F66

Heavy Duty / Wet Areas – F. Ball & Co F73 Plus, F81